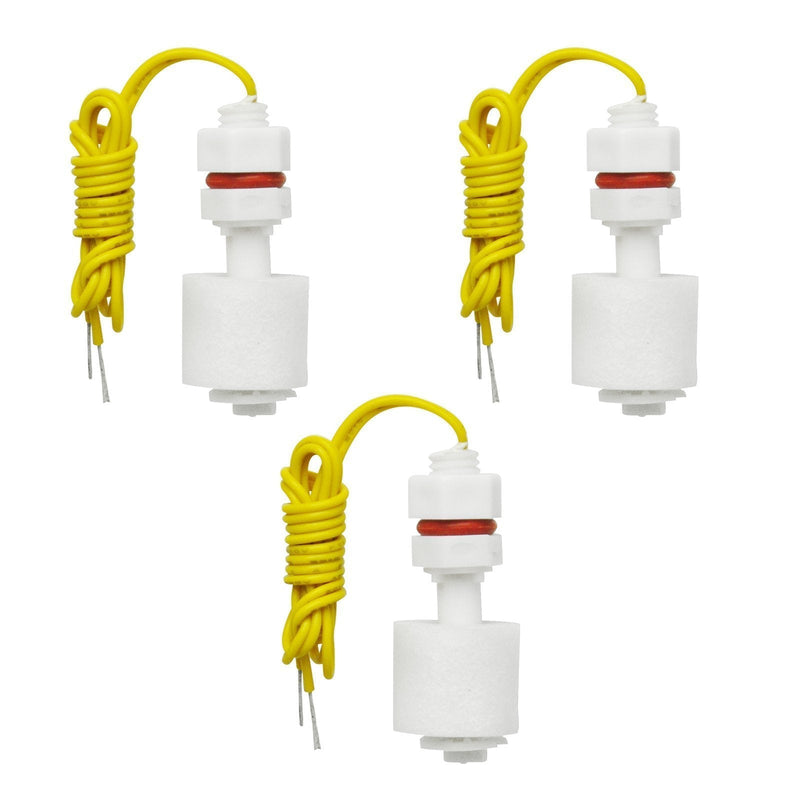

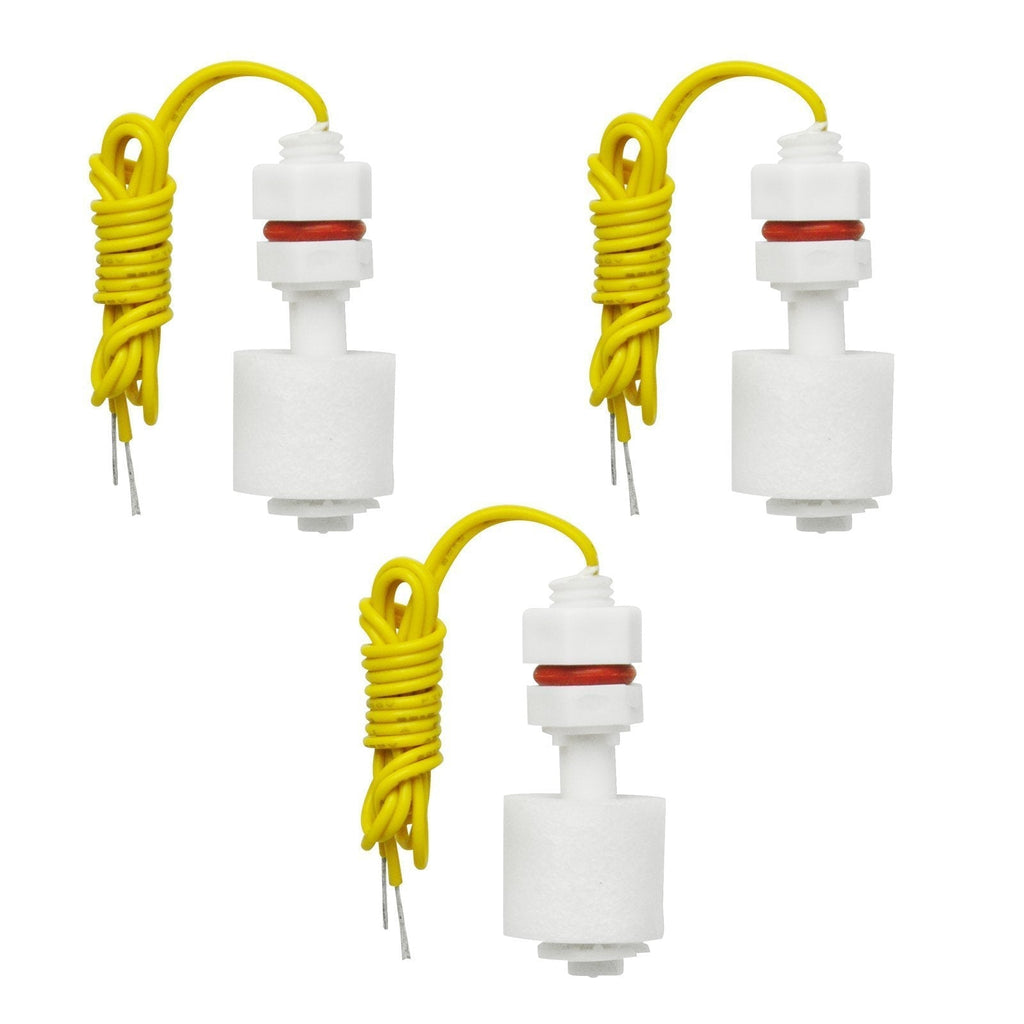

Taidacent Non Contact Liquid Level Sensor Contactless Water Level Sensor Externally Attached Pipe Water Float Switch NPN Output Capacitive

Taidacent Non Contact Liquid Level Sensor Contactless Water Level Sensor Externally Attached Pipe Water Float Switch NPN Output Capacitive

Parameter Product model: XKC-Y26-NPN Supply voltage(Vin):DC 5-12V Output mode: Switch quantity (high pulse effective) electric current: 5mA The output voltage(high pulse): Vin; The output voltage(low pulse): 0V; The output current: ≤100mA Response time: 500mS Working temperature: -20~85℃ Sensor sensitivity Pipe outer diameter D(mm) D≥100,Sense container wall or tube wall thickness L(mm) 20±2; Pipe outer diameter D(mm) 100>D≥80 ,Sense container wall or tube wall thickness L(mm) 15 ± 2; Pipe outer diameter D(mm) 80>D≥60,Sense container wall or tube wall thickness L(mm) 12 ±1.5;Pipe outer diameter D(mm) 60>D≥40,Sense container wall or tube wall thickness L(mm) 7 ±1.0;Pipe outer diameter 40>D≥30,Sense container wall or tube wall thickness L(mm) 5 ±1.0; Outer diameter of pipe D(mm) 30>D≥20,Sense container wall or tube wall thickness L(mm) 3 ±1.0; pipe outer diameter D(mm) 20>D≥10,Sense container wall or tube wall thickness L(mm) 1.5 ±0.5 Applicable pipe diameter range ≥10mm Liquid level accuracy ±1.5mm humidity 5%~100% Material PC V0 Fireproof material Waterproof performance IP65 Installation method Install into a flat cistern as shown in the figure above The height of the sensed liquid level is related to the sensitivity of the sensor. The higher the sensitivity, the lower the sensed liquid level Note: The liquid level is sensed in the upper and lower edges of the sensor, which is normal. The induction sheet can be tightly attached to the pipe with strong glue, or it can be tightened with the pipe with a nylon cable tie. Try to avoid metal and other parts where the probe is installed, so as not to affect the detection. Pipes made of non-metallic materials with a smooth surface, uniform thickness, tight material, and good insulation performance; such as glass pipes, plastic pipes, PC/PVC/PPR pipes, non-absorbent ceramic pipes, acrylic pipes, rubber pipes, etc. or their composites Pipes made of materials. How to install to the water pipe Install to the non-metal water pipe type as shown Sensitivity adjustment If the non-contact liquid level sensor cannot detect or the detected liquid level is too high from the Y26 sensor. The sensitivity knob can be adjusted with a small screwdriver, and there are two setting methods: 1. Low sensitivity adjustment: turn counterclockwise to increase sensitivity. 2. High sensitivity adjustment: turn clockwise to lower the sensitivity Product size and physical map Y26 wiring diagram of various models NPN output drives small electric relays (coil current ≤ 100mA) working principle 1.When the black line is suspended, it is normally open output: When liquid is sensed, the transistor is turned on and closed, and the relay is energized and closed; When no liquid is sensed, the transistor will be cut off and the relay will not be closed when the power is turned off; 2.When the black wire is grounded (connected to the negative pole of the power supply 0V), it is normally closed output: When liquid is sensed, the transistor will be cut off and the relay will not be closed when the power is turned off; When no liquid is sensed, the transistor is turned on and closed, and the relay is energized and closed;

Product Features

- The intelligent non-contact liquid level sensor uses advanced signal processing technology and high-speed signal processing chip to break through the influence of the wall thickness of the container and realize the true non-contact detection of the liquid level in the closed container.

- The liquid level sensor (probe) is installed above and below the outer wall of the container to be tested (the high and low positions of the liquid level). The non-metallic container does not need to be opened, and the installation is simple and does not affect the production.

- The liquid level of various toxic substances, strong acids, strong alkalis and various liquids in the high-pressure closed container can be detected.

- The liquid to be tested is required to be electrically conductive, the contact surface is non-metal, and the pipe is easy to install and can be widely used.

- NPN output: If there is induction, the output is low level; no induction, disconnected